System

Smart Industrial Control Software System

Smart Quality Paging System

The Smart Quality Paging System triggers an alarm when breakdowns occur over the production process and during the monitoring of the production process. It also enables access to information of all breakdowns that have taken place during the production process. During the production process, the alarm information is automatically sent to the control centre which will automatically send the alarm information simultaneously through three methods: The different alarm types are indicated on the paging system with different colors. The system instantly notifies the relevant personnel to take remedial action while the display screen in the workshop shows the alarm location and type.

Smart Main Line Equipment Management System for the Car Industry

With over 20 years of manufacturing experience, we have produced a customisable Smart Manufacturing management system for car industry software systems based on improved smart, rationalized and integration management concepts. Based on traditional software, the system has undergone improvements for better management processes such as planning, control and decision-making. The software incorporates the core concepts of Industry 4.0 whereby “Industrialistion” and “Informatisation” are merged together. It improves management and production processes in a smarter and more user-friendly way. The software features apply to the following areas:

● Manufacturing Site: Creates a transparent manufacturing process while agilely responding to various glitches during the manufacturing process, ensuring the orderly execution of the production process.

● Production Planning: Offers rational production arrangements, reducing bottleneck issues while improving overall efficiency.

● Production Quality: Offers more accurate prediction of trends and more effective control of defects.

● Manufacturing Decision-Making: Offers more detailed information as basis for the decision-making process, allowing for a more direct decision-making process and more rational decision-making results.

● Production Logistics: Reduces logistical bottlenecks while boosting the accuracy of logistics distribution and minimizing downtime due to the lack of materials.

● Office Automation: Solves inconsistent data issues of every process component, reducing communication costs and supporting collaborative production.

Manufacturing Execution System (MES)

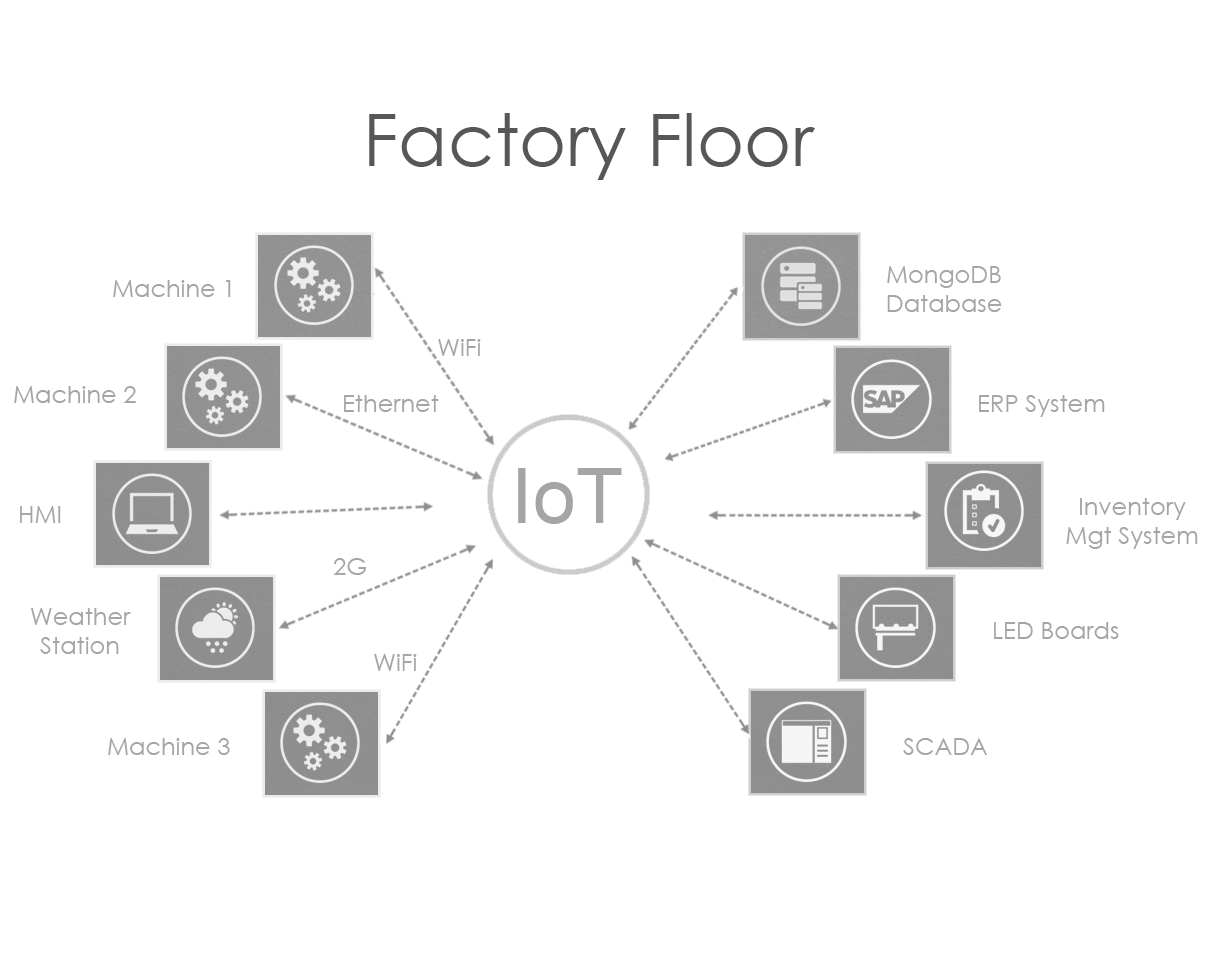

Manufacturing execution systems (MES) are computerized systems used in manufacturing, to track and document the transformation of raw materials to finished goods. MES provides information that helps manufacturing decision makers understand how current conditions on the plant floor can be optimized to improve production output.

MES work in real time to enable the control of multiple elements of the production process (e.g. inputs, personnel, machines and support services).

● Effectively management of manufacturing process control

● Enhance after-sales service with code tracking (barcode, QR, RFID & etc)

● Responsive & improve product quality management

● Substantial reduction in manpower capital, elevate productivity of field management;

● Obtain utilization status of machine and equipment

● Real-time optimization of manufacturing production and supply chain networks

● Dynamically statistical report boost the company's core competitiveness & improvement