Product & Services

Services and Consulting

Preliminary Design and Consultancy for Manufacturing Systems

Logistics Simulation Objectives

Production Capacity Assessment: Analysis logistics design and generate logistics simulation analysis reports to provide decision-making support for the production process.Identify the bottlenecks in logistics designs while providing feasible solutions and implementing recommendations. To also provide recommendations on how to optimize the logistics process and reduce inventory.

Digital 3D Virtual Simulation

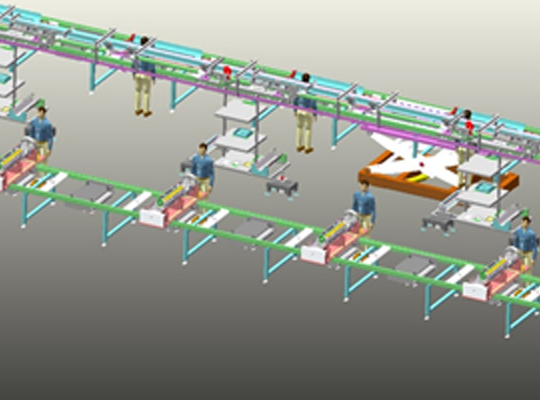

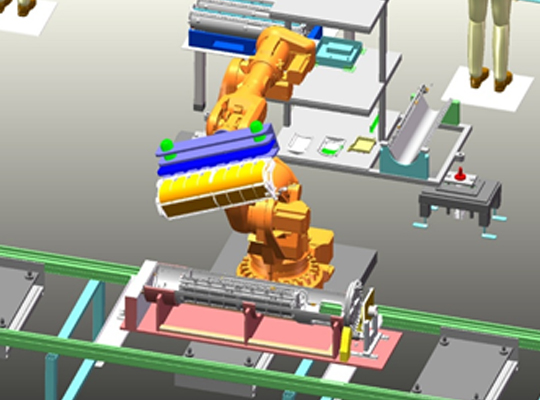

3D Virtual Simulation employs three-dimensional modeling technology to build 3D real-world scenes. Driven by a certain software environment, 3D scenes respond to user input and correspond accordingly with different user activities whereby these responses are showcased in a 3D environment. The key technologies include a dynamic modeling environment, real-time 3D graphics generation, stereoscopic display, sensor, application development tools and system integration technologies. Digital 3D Mechanical Engineering Simulation and Digital 3D Virtual Simulation technologies are applied. Diverse methods enable clients to design manufacturing processes and perform scene simulations such as logistics simulation. Logistics Simulation: This system, which draws from computer simulation technologies and virtual real-world methods, performs modeling and simulation on every component of the logistics system (such as the storage system, transportation system, etc.), simulating actual operation situations in order to guide the preliminary design process of the logistics system and subsequent operations management process. The system also borrows from simulation technologies (in terms of their experimental, quantifiable, speedy, scientific and economical characteristics as well as good random performance) for the design and decision-making processes of production systems which involve complex multi-objective discrete dynamic systems. Logistics simulation involves an entire logistics network of distribution centres, warehouse storage systems, picking systems and transportation systems as well as coordination and partnerships among various departments.

Preliminary Design and Consultancy for Indoor Logistics & Process Layout and Analysis for Clients' Products

Having amassed rich planning and design know-how over 20 years of industry experience, we offer clients highly specialised preliminary design and consultancy services for indoor logistics while also laying out and analysing the production process in order to produce workshop designs that are better tailored to meet the needs of individual clients. We consolidate our understanding of customer needs and collect relevant information, following which we produce a layout master plan (i.e. the process layout diagram) upon analysing and laying out the design. We then proceed to generate the master plan through validating the process with Digital 3D Virtual Simulation.

Automatic Conveyor System

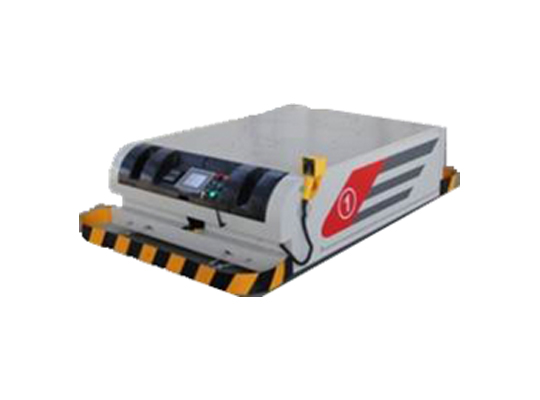

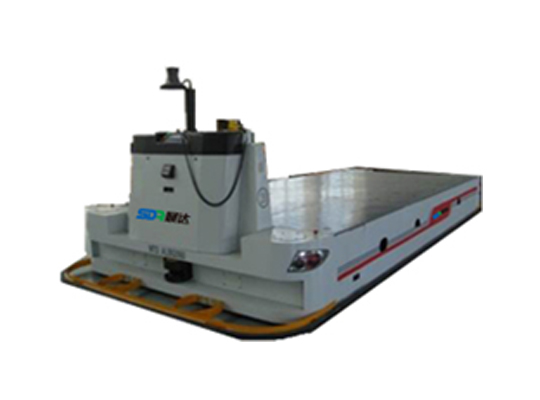

AGV Automated Guided Vehicle

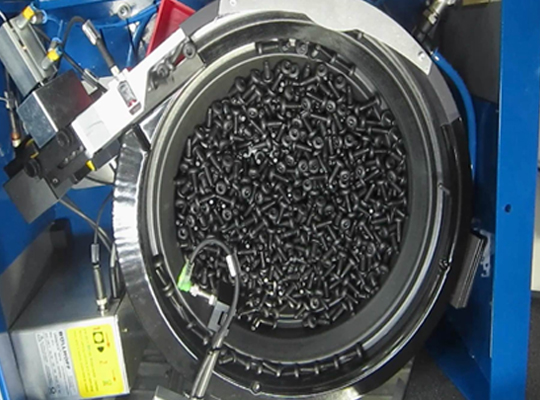

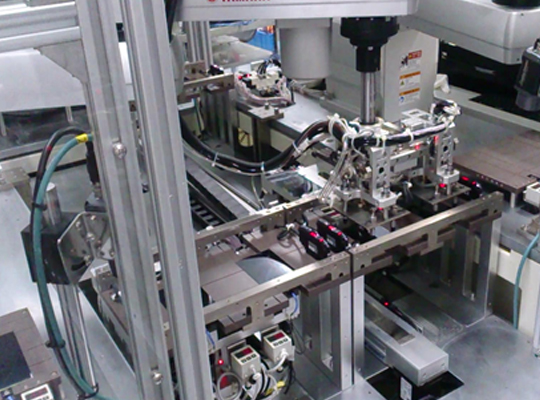

Intelligent Assembly System

Intelligent QC system for LCD panel

Automatic material loading